Dependable structures built to support the full range of mining and mineral operations.

Mining and mineral operations sites require a synthesized network of roads, crossings, tunnels and dump walls that support processing facilities. Because this infrastructure is intended to perform at maximum production levels under heavy loading, our professional engineers develop unique solutions to build durable structures dependent on the use of high-end, sustainable construction materials.

Terre Armée delivers materials that are tailored in a way that makes installation rapid, predictable and dependable.

Processing dump walls

Mining operations involve heavy trucks for material handling. Dump walls, or tip walls allow run-of-mine (ROM) trucks to access the top of a crusher pit for transferring the raw material into a hopper by tipping or bottom dumping. Our experience with ROM dump walls extends over 45 years having designed Reinforced Earth® MSE walls for some of the largest primary crushing facilities at the world’s largest mining operations. These walls can reach heights of over 40m tall, and carry extreme live loads, even under severe climatic and local conditions.

We optimize the design of your structure on the basis of best selection of materials to suit your project. The choices for facing elements include precast concrete panels, TerraMet™ semi-elliptical steel panels, or TerraTrel® welded wire steel mesh. Soil reinforcements come in the form of high-adherence steel strips, geosynthetic strips, or steel bar mats.

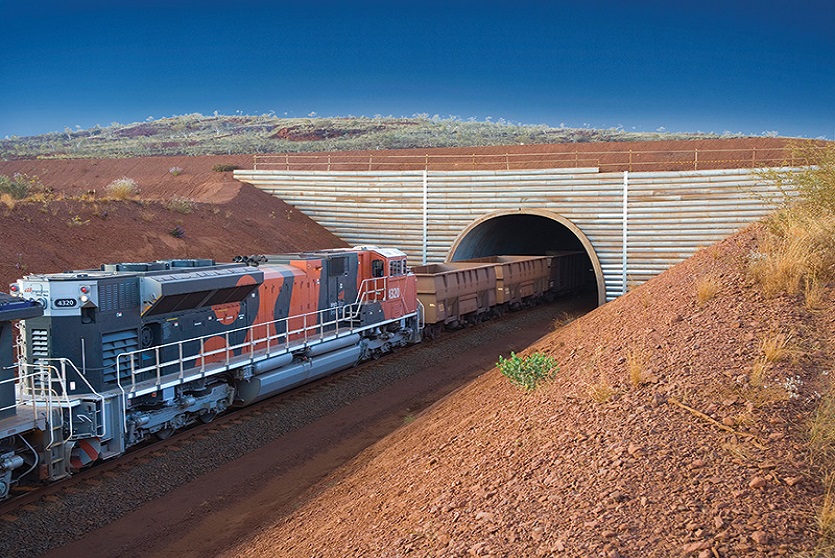

Precast concrete tunnels

TechSpan® precast concrete arches are the ideal solution for the construction of precast segmental tunnels throughout mining sites. TechSpan® has the capacity to withstand loads from the highest mineral stockpiles and the heaviest mine plant activity. Our TechSpan® solution is commonly used to build:

- Reclaim conveyor tunnels

- Rail and vehicle tunnels

- Short-span bridges

- Shaft portals

- Rockfall sheds

- Utility vaults and pipeline cover

Storage “slot” bunkers

Our solutions for storing and reclaiming ore, minerals, coal, and other mined materials typically consist of inclined Reinforced Earth® walls, built linear or octagonal in plan. Most of these structures are built inverted, below ground, although may be set above ground. These walls are built with facings set at a calculated incline for drawdown. These slope-faced walls are referred to as “V-slots” or bunkers. Reinforced Earth® slots have now been constructed on four continents with storage capacities ranging from 2,000 tonnes to 150,000 tonnes each, with depths reaching above 25m.

Reservoirs, tanks, ponds and pipelines

Mining operations require liquids storage and sediment separation facilities. We provide highly-engineered solutions to build and protect:

- Reservoirs

- Settling basins

- Tailings dams and ponds

- Frothing tank pads

- Leaching pads

- Hydro-transport pipelines

Using Reinforced Earth® walls, built watertight when necessary, in combination with geosynthetic clay liners and geocomposite drainage systems will mitigate and control leakage, seepage, and undermining from erosion and chemical assault.

Access roads

Mine sites are often located in remote areas having variable soils. When necessary to build upon low bearing-capacity soils, intensive heavy truck and machinery trafficking will eventually cause deformation to superficial roadway layers if not reinforced. Such deformations may slow down operations and decrease on-site productivity, while increasing risks of accidents.

A simple and economical solution is to reinforce access roads using geogrids combined with aggregates to build a composite layer. Our soils experts will assist you in developing solutions using our high-performance geogrids to reduce the amount of aggregates required.

Our solutions result in significant savings in up-front costs, and mitigate the effects of rutting, which in turn reduces long-term maintenance costs.

Risk mitigation

Our specialists will address natural risk mitigation (such as rockfall and avalanche) with solutions to minimize interruptions to operations. We have expertise in assessing the capacity of existing structures to accept increased loads through upgrades, or to find solutions to make expansions, re-use, or repairs.

Benefits

Extreme load bearing capacity

Extreme load bearing capacity

Reinforced Earth® structures have extreme load bearing capacity and are resistant to vibrations, making them them ideal for supporting the live loads of heavy industrial vehicles and demanding activities, such as crushing and screening.Flexibility

Flexibility

Reinforced Earth®structures can be built to very tall heights, over large surfaces, and are flexible to accommodate various geometrical requirements, such as sloped surfaces, and straight or curved alignments, making it a great solution for dump walls, among other applications.Easy and rapid installation

Easy and rapid installation

Our structures are easy and quick to install. Offering a predictable installation requiring little space, they are an ideal choice on active mining sites, where little disruption to activities can be tolerated.Related applications